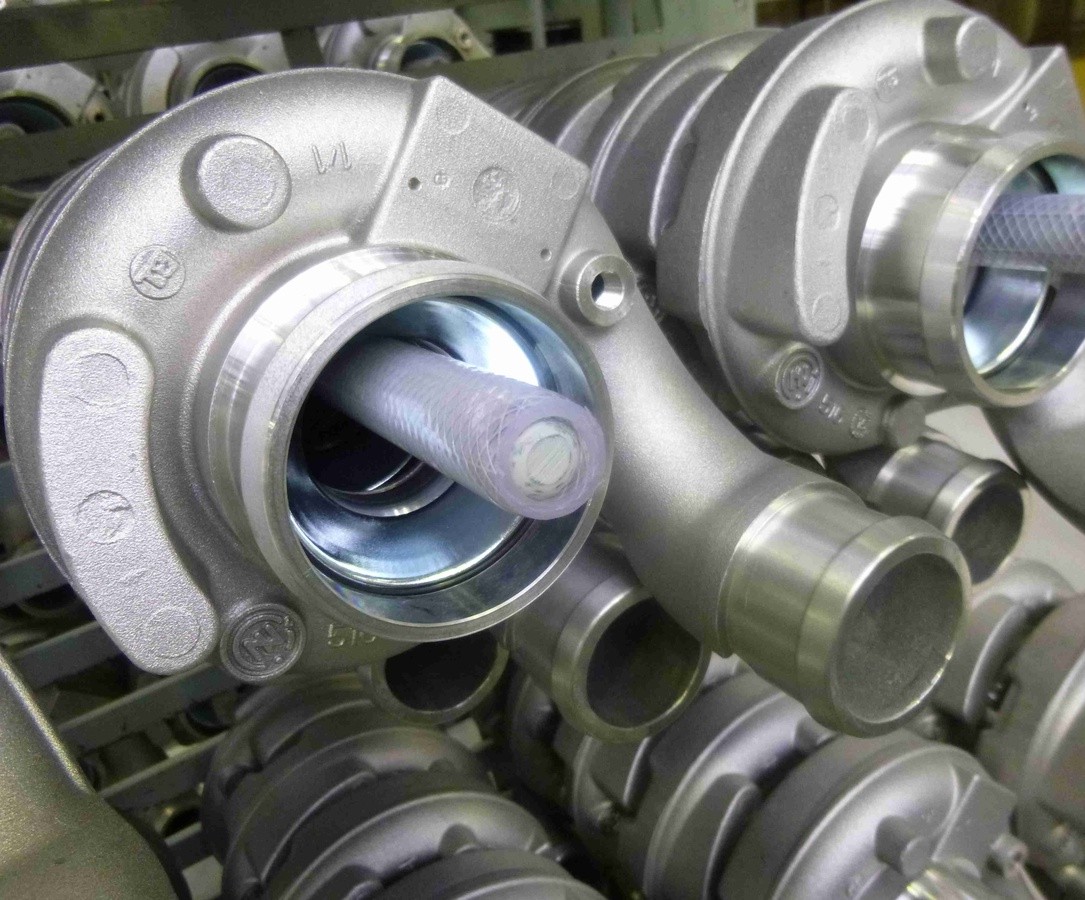

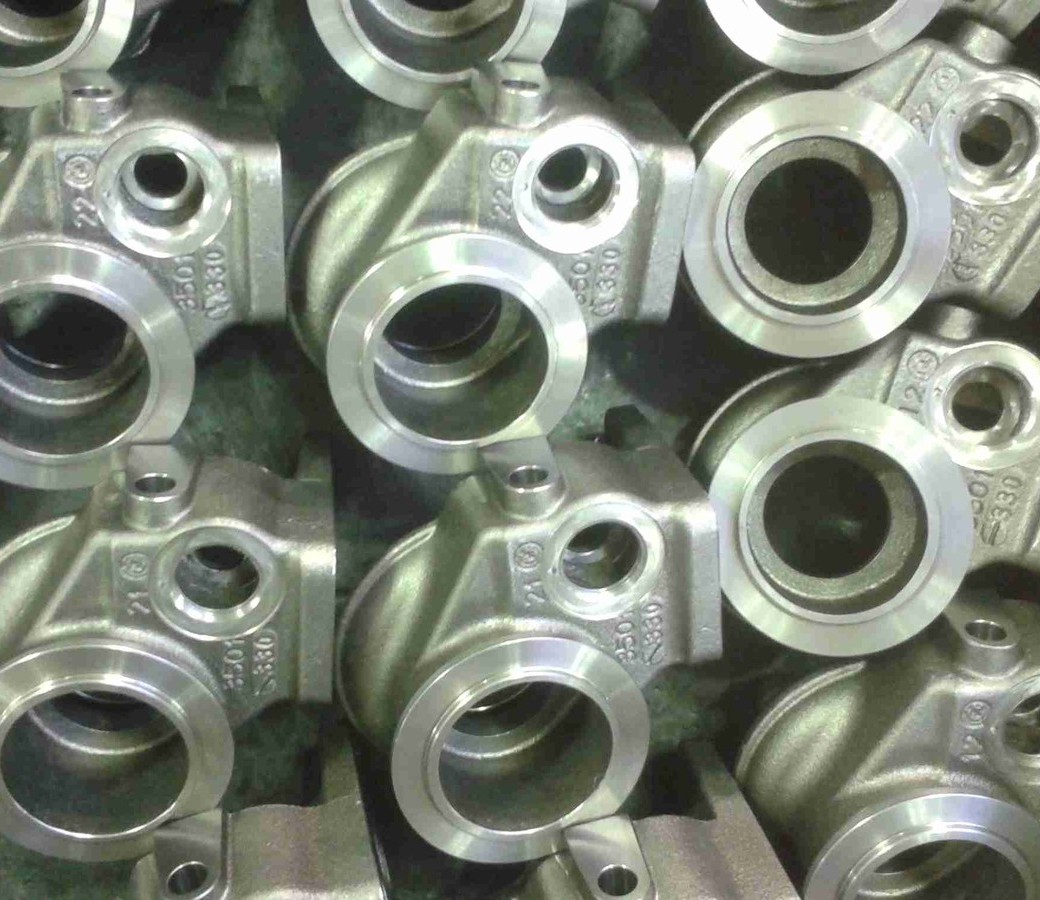

High percentage of our own production compared with other turbocharger manufacturersCastings (compressor housing, bearing housing, turbine housing) are mainly provided by ČZ foundries so we make manufacturing and logistics costs more effective.

The technologies we use guarantee not only a high quality surface but also precise casting - so that our turbochargers can achieve the maximum efficiency.

The latest technologies are used when machining parts, including a 5-axis Hermle milling centre for milling compressor wheels using specialized CAM software Concepts NREC.

These technologies mean we can constantly achieve high productivity and the highest quality in our manufacturing process.